Introduction to PEEK Electrical Connector Parts

PEEK connectors, chiefly crafted from Polyetheretherketone (PEEK), stand as high - performance electrical connection solutions. PEEK, a semi - crystalline thermoplastic, imparts unique qualities, rendering these connectors suitable across diverse industries.

Material Characteristics of PEEK

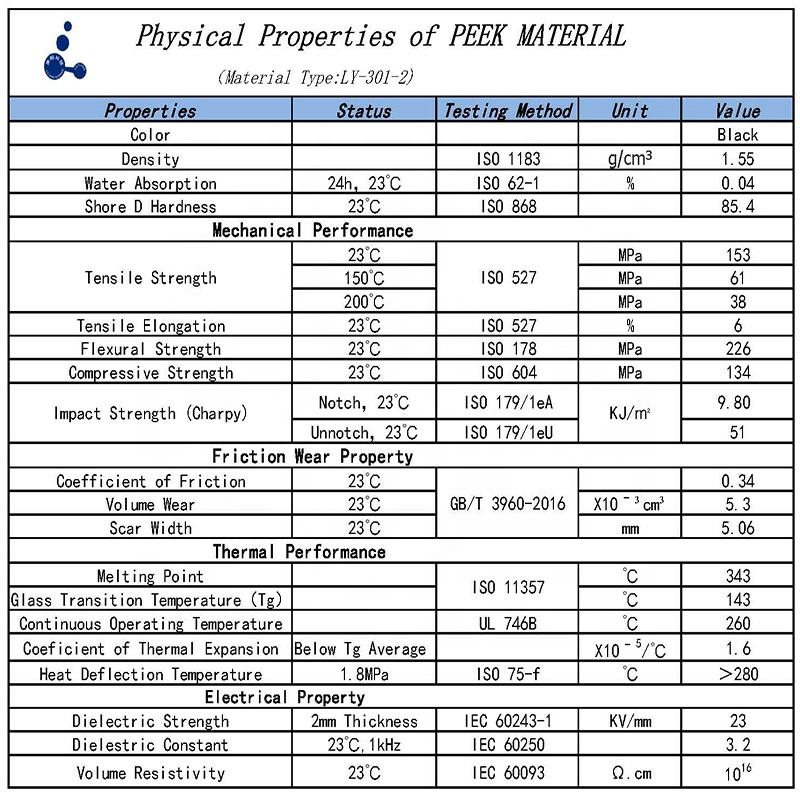

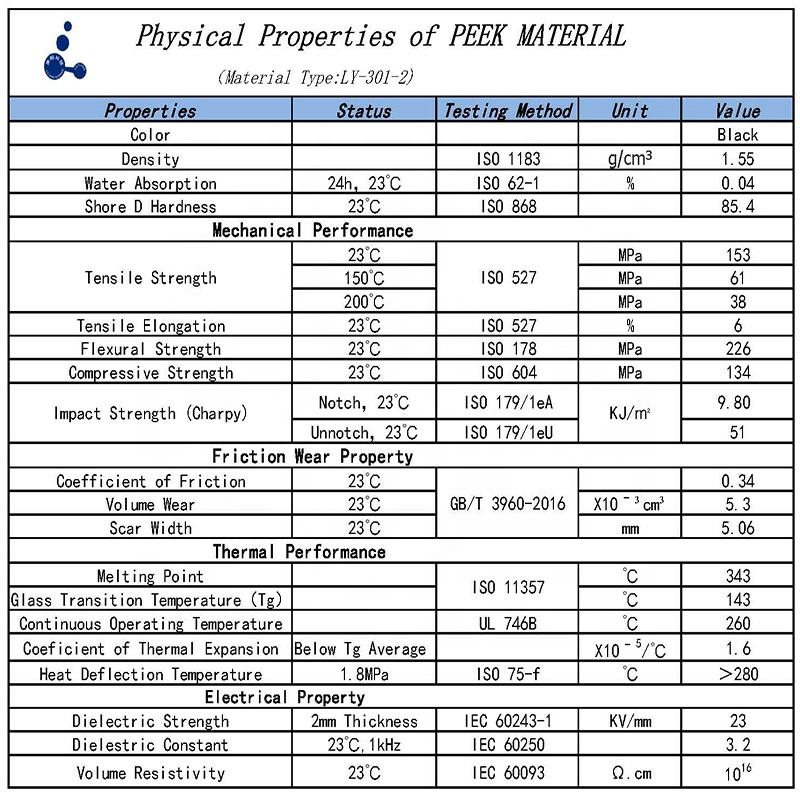

High Mechanical Robustness

PEEK exhibits notable tensile strength. In the aerospace industry, where connectors endure vibrations and extreme G - forces, this strength is indispensable. For instance, within aircraft engine wiring, PEEK connectors uphold stable electrical pathways, minimizing connection failures and ensuring the seamless operation of flight - essential systems.

Exceptional High - Temperature Endurance

PEEK functions effectively at elevated temperatures. With a glass transition temperature around 143°C and a melting point of approximately 343°C, it maintains its form and functionality. In medical autoclaves for sterilization and industrial high - heat zones such as steel mills, PEEK connectors can withstand the heat without degradation.

Superior Electrical Properties

PEEK has a low dielectric constant and dissipation factor across a wide range of frequencies. This makes it ideal for high - speed data transfer. In telecommunications and data centers, PEEK connectors mitigate signal attenuation and distortion, enabling the smooth and precise transmission of large - volume data.

Manufacturing Process of PEEK Connector Components

The production of PEEK connector components typically involves precision injection molding. Owing to PEEK's high melting point, specialized high - temperature injection molding equipment is required. These machines uniformly melt PEEK and precisely inject it into molds, enabling the creation of intricate shapes with tight tolerances. Post - molding, processes like machining, surface treatment (such as plating to enhance corrosion resistance and electrical conductivity), and assembly are carried out to complete the PEEK connector.

Applications in Various Fields

Aerospace Sector

Within the aerospace domain, PEEK connector components find extensive application. In aircraft avionics, they play a crucial role in transmitting navigation, communication, and flight - control signals. In engine control systems, they can endure the high - temperature and high - vibration conditions of the engine compartment. For example, in engine wiring harnesses, they ensure reliable data transfer between sensors and actuators, and in aircraft communication setups, they support high - speed data transfer for effective communication with ground stations.

Medical Equipment Industry

PEEK connector parts are vital in the medical field, especially in advanced devices like MRI machines, X - ray equipment, and surgical robots. PEEK's biocompatibility makes it suitable for parts in contact with patients. In MRI devices, it does not interfere with the magnetic resonance process. In surgical robots, it transfers power and control signals for accurate operations. Additionally, its heat resistance allows for easy sterilization, maintaining high - level hygiene in medical facilities.

Industrial Control Area

In industrial automation, PEEK connector parts are employed in Programmable Logic Controllers (PLCs), motor drives, and sensors. In harsh industrial environments, such as in robotic arms, PEEK connectors ensure stable electrical connections, contributing to the accurate operation of the automation system and maintaining seamless industrial control.

Advantages of PEEK connector components:

PEEK connector components can choose appropriate specifications according to application requirements.

PEEK Electrical Connector are compatible with various types of cables and circuit boards.

The PEEK connector is designed with precision and strict production process control, ensuring the long-term reliability and stability of the product.

The PEEK connector design takes into account simplicity of use and maintenance requirements in the later stages.

Details of PEEK connector:

The application of PEEK electrical connector parts:

Due to its excellent performance, PEEK connector components have been widely used in many fields, including aerospace, medical equipment, industrial control, automotive, communication, and more

Why did you choose us?

We provide customized services and can customize electrical connector components of different specifications according to the specific needs of customers.

We have an efficient supply chain management system that can deliver quickly and meet the urgent needs of customers.